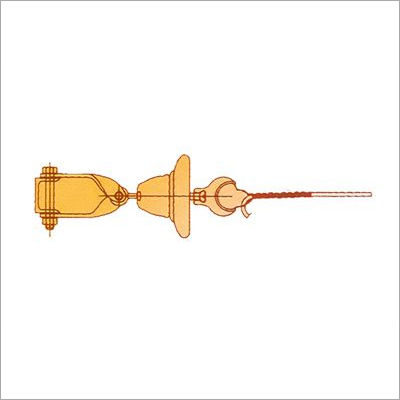

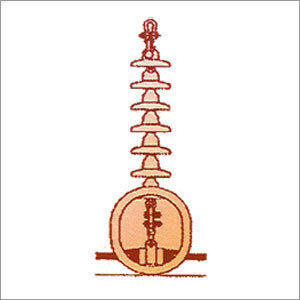

Electrical Insulator Fittings

1400 INR/Set

Product Details:

- Product Type Electrical Insulator Fittings

- Material Galvanized Steel, Malleable Iron, or Alloy Steel

- Capacity Up to 33 kV

- Protection Corrosion Resistant, Weatherproof

- Application Overhead Transmission Line, Substation, Distribution Line

- Size Customized, Standard Sizes Available

- Dimension (L*W*H) As per Specification/Type

- Click to view more

X

Electrical Insulator Fittings Price And Quantity

- 10 Set

- 1400.00 - 2500.00 INR/Set

- 1400 INR/Set

Electrical Insulator Fittings Product Specifications

- Electrical Insulator Fittings

- Up to 33 kV

- Metallic Silver, Hot Dip Galvanized Finish

- Customized, Standard Sizes Available

- As per Specification/Type

- Overhead Transmission Line, Substation, Distribution Line

- Galvanized Steel, Malleable Iron, or Alloy Steel

- Corrosion Resistant, Weatherproof

Electrical Insulator Fittings Trade Information

- as per order Per Week

- According to order Week

- as per customer requirement

- All India

- ISO 9001:2008

Product Description

Years of involvement in this domain has enabled us to manufacture and supply Electrical Insulator Fittings. These fittings are demanded by power plants and factories across the market due to its precise design and rigidity. Manufactured using quality components and materials, these fittings can provided high level of insulation from electricity. Our high-ranking professionals examine and test all the Electrical Insulator Fittings to ensure quality products to our clients. Furthermore, we store all our products in our huge warehousing facility to supply on-demand.

Features:

-

Perfect design

-

Durable

-

Corrosion resistant

-

Rigid construction

Superior Corrosion Resistance

Our electrical insulator fittings are treated with hot dip galvanization and rust-proof coatings, ensuring exceptional protection against corrosion, weather exposure, and chemical reactions. This advanced surface treatment extends the products lifespan even in challenging outdoor environments, making them ideal for high-voltage transmission lines and substations.

Adherence to International Standards

Each fitting is manufactured in compliance with IS 2486 and IEC standards. This guarantees quality, safety, and performance reliability, providing peace of mind to utilities, contractors, and engineers. Standardized production facilitates straightforward integration into both new and existing infrastructure projects.

Flexible Connection Types and Sizes

Choose from bolted, clamped, or pin-connected fittings to match your installation needs. Both standard and custom sizes are available, accommodating capacities up to 33 kV, and ensuring seamless adaptation across a wide array of transmission and distribution setups. Mechanical strengths are tailored as per application requirements.

FAQs of Electrical Insulator Fittings:

Q: How do hot dip galvanized and rust-proof coatings benefit electrical insulator fittings in outdoor environments?

A: Hot dip galvanized and rust-proof coatings form a protective barrier that prevents moisture and corrosive elements from degrading the fittings, ensuring durability and reliability in exposed locations like transmission lines and substations.Q: What standards are followed in the manufacturing process of these insulator fittings?

A: All electrical insulator fittings are manufactured in strict adherence to IS 2486 and IEC standards, which ensures product quality, safety, and compatibility with international utility requirements.Q: When should I use bolted, clamped, or pin connected fittings for my transmission system?

A: The choice depends on the specific mechanical strength required, installation preferences, and environmental conditions. Bolted connections are favored for heavy-duty applications, clamped fittings offer versatility, while pin connections are ideal where quick installation and removal are necessary.Q: Where are these electrical insulator fittings typically installed?

A: These fittings are primarily used in outdoor environments, including overhead transmission lines, substations, and distribution networks, where they secure and support electrical insulators handling up to 33 kV.Q: What accessories are available with these fittings, and can they be customized?

A: Bolts, nuts, and washers are included as accessories and are available on demand. Both accessories and main fittings can be supplied in standard or customized sizes to suit your project specifications.Q: What is the mechanical strength range for these fittings, and how should I select the appropriate one?

A: Mechanical strength varies from 5 kN to 120 kN, depending on the fitting type. Selection should be based on load requirements, system voltage, and environmental factors to ensure optimal performance and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Electrical Hardware' category

Back to top