Pole Line Hardware

Product Details:

- Product Type Pole Line Hardware

- Material Mild Steel/High Tensile Steel

- Welding Standard IS: 816/IS: 9595

- Capacity Depend on size and application

- Application Overhead transmission and distribution lines

- Galvanization Standard IS 2629/ISO 1461

- Out Coating Hot Dip Galvanized

- Click to view more

Pole Line Hardware Price And Quantity

- As per order Piece

Pole Line Hardware Product Specifications

- Up to 33 kV and above

- Silver/Grey

- Depend on size and application

- Various (as per design: eye, clevis, straight, etc.)

- IS: 816/IS: 9595

- As per customer drawings or IS/IEC design

- IS/IEC standards

- Pole Line Hardware

- Galvanized

- IS 2629/ISO 1461

- 4 mm to 12 mm

- Hot Dip Galvanized

- Customizable

- Overhead transmission and distribution lines

- Mild Steel/High Tensile Steel

Pole Line Hardware Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- as per order Per Week

- According to order Week

- as per customer Requirement

- All India

- ISO 9001:2008

Product Description

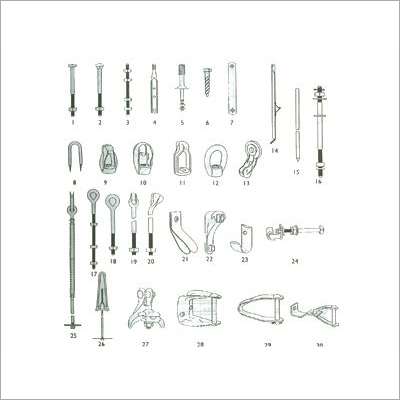

With our huge expertise in this domain, we are able to manufacture and supply high quality Pole Line Hardware. These components are used in the construction of huge pole line and electrical towers. Made using high quality materials, our products are very sturdy and durable. Offered hardware is carefully inspected after the manufacturing process to ensure flawless nature. Moreover, our huge transportation facility has enabled us to deliver the Pole Line Hardware within a specific time-frame. Our range comprises:

-

Machine Bolt

-

Carriage Bolt

-

Double Arming Bolt

-

Pole Top Pin

-

Insulator Pin

-

Lag Screw

-

Cross Arm Brace

-

Staple

-

Thimble Eyenut

-

Twin Eyenut

-

Straight Thimbleyelet

-

Oval Eyenut

-

Angle Thimble-Eyelet

-

Alley Arm Brace

-

Ground Rod

-

Spool Bolt

-

Double Arming Eyebolt

-

Oval Eye Bolt

-

Straight Thimble-Eye Bolt

-

Angle Thimble-Eye Bolt

-

Guy Attachment

-

Guy Attachment

-

Guy Hook

-

Transformer Trainer Bracket

-

Stay Rod Tubular Type

-

Bow Type Stay Rod & Plate

-

Angle Suspension Clamp

-

Insulated Secondary Clevis

-

Insulated Swinging Clevis

-

Insulated Swinging Clevis

Reliable Corrosion Resistance for Demanding Environments

Every piece of our pole line hardware is hot dip galvanized in accordance with IS 2629 or ISO 1461 standards, ensuring exceptional rustproof protection. This enhances longevity in harsh outdoor climates and minimizes maintenance, even under challenging weather conditions.

Engineered for Strength and Safety

Our hardware supports loads up to 120 kN, with thicknesses ranging between 4 mm and 12 mm. Rigid construction and adherence to welding standards IS: 816/IS: 9595 guarantee structural integrity and safety in critical transmission and distribution scenarios.

Easy and Versatile Installation

Pole line hardware is designed for straightforward bolted or clamped mounting, compatible with various shapes (eye, clevis, straight) as per technical or customer drawings. This allows for flexible usage on multiple application setups, reducing installation time and complexity.

FAQs of Pole Line Hardware:

Q: How is the corrosion resistance of the pole line hardware achieved?

A: Corrosion resistance is ensured through hot dip galvanization, done as per IS 2629 or ISO 1461 standards. This rustproof coating provides long-lasting protection for hardware exposed to outdoor environments.Q: What materials are available for the pole line hardware?

A: The hardware is manufactured from mild steel or high-tensile steel, both engineered for durability and performance in transmission and distribution line applications.Q: Where can this pole line hardware be used?

A: It is designed for use in overhead transmission and distribution lines, making it suitable for various outdoor electrical infrastructure projects across India.Q: What is the installation process for this hardware?

A: Installation is carried out using bolted or clamped mounting methods, ensuring easy and secure attachment to poles, with compatibility for a wide range of accessories like clamps, brackets, and stay sets.Q: When should I choose this hardware with high load capacity?

A: Select these components when your project requires support for loads up to 120 kN, especially in settings with heavy mechanical demand or stringent safety requirements.Q: How does this product benefit my electrical installation?

A: High corrosion resistance, strong construction, and easy integration make it a reliable choice for safe, long-lasting, and maintenance-minimized installations in outdoor settings.Q: What packing options are available for delivery?

A: Products can be packed in jute bags, wooden crates, or cartons to ensure safe handling and transport suited to your needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+