Call Us08045800593

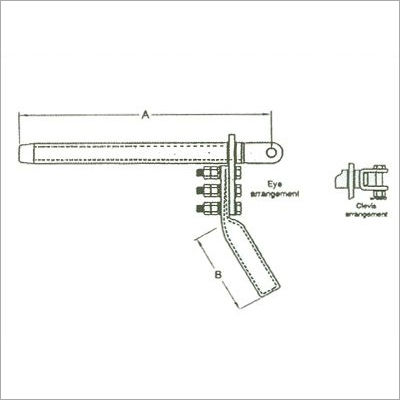

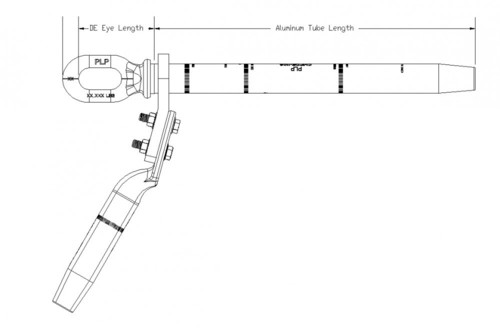

Compression clamp and jumper

400 INR/Set

Product Details:

- Product Type Compression Clamp and Jumper

- Material High Tensile Aluminum Alloy / Steel

- Welding Standard As per IS Specifications

- Capacity Up to 2000 A

- Application Transmission Lines, Substations, Conductors Jointing

- Galvanization Standard IS 2629/IS 4759

- Out Coating Hot Dip Galvanized

- Click to view more

X

Compression clamp and jumper Price And Quantity

- 400.00 - 3000.00 INR/Set

- 10 Set

- 400 INR/Set

Compression clamp and jumper Product Specifications

- 6 mm to 12 mm (customizable)

- Rectangular/Jumper/Elliptical as per drawing

- IS 2629/IS 4759

- Hot Dip Galvanized

- Varies as per design

- Up to 400 kV

- Customized as per Requirement

- IS/IEC 61284

- High Tensile Aluminum Alloy / Steel

- Compression Clamp and Jumper

- Corrosion Resistant Coating

- Up to 2000 A

- As per IS Specifications

- Transmission Lines, Substations, Conductors Jointing

Compression clamp and jumper Trade Information

- as per order Per Week

- According to order Week

- as per customer requirment

- All India

- ISO 9001:2008

Product Description

We have emerged as a reputed organization, engaged in manufacturing and supplying best quality Compression clamp & Connectors. These connectors are manufactured in our huge infrastructure facility, installed with advanced machines and tools. High-grade materials required in the manufacturing process are supplied by our most renowned vendors of the market. These Compression Connectors offer excellent performance.

Features:

-

Fine finish

-

Excellent design

-

Durable

Superior Corrosion Resistance

Our clamps and jumpers employ advanced surface treatments and hot dip galvanization, following IS 2629/IS 4759 standards, which provide outstanding protection against corrosion. This ensures a longer lifespan even in challenging outdoor conditions, minimizing maintenance needs and enhancing operational reliability for transmission networks.

Flexible Design & Mounting Options

We offer customized designs tailored to specific requirements, with shapes available in rectangular, jumper, or elliptical formats as per drawing. Mounting can be bolt type or compression type, enabling simple, rapid installation, and ensuring secure fittings to various conductor sizes across substations and transmission lines.

FAQs of Compression clamp and jumper:

Q: How are compression clamps and jumpers installed on conductors?

A: Compression clamps and jumpers are installed using a bolt-type or compression-type mounting method. Their design allows for quick and straightforward fitting, typically supplied with fixing bolts and washers for easy attachment to conductors ranging from 16 mm to 800 mm.Q: What materials are used in manufacturing these clamps and jumpers?

A: The products are made from high tensile aluminum alloy or steel, providing excellent strength and durability. The surfaces undergo corrosion-resistant treatments and hot dip galvanization per IS 2629/IS 4759 standards for long-term outdoor use.Q: When should I use a customized design for my application?

A: Customized designs are recommended when your project requires specific shapes, thicknesses, or installation features that differ from standard models. We offer tailored solutions to fit unique drawings and operational requirements, ensuring optimal performance and compatibility.Q: Where are compression clamps and jumpers typically used?

A: These devices are mainly utilized in transmission lines, substations, and jointing of conductors for both overhead and outdoor applications. Their robust construction and protective coatings make them ideal for heavy-duty environments across diverse locations.Q: What is the process for ensuring compliance with industry standards?

A: All products are manufactured and tested according to IS, IEC, and ASTM standards. This includes adherence to galvanization standards (IS 2629/IS 4759), welding specifications, and quality benchmarks to maintain reliability and safety.Q: What are the main benefits of using these clamps and jumpers?

A: They provide high tensile strength (minimum 45 kN), excellent corrosion resistance, reliable electrical connectivity, and easy installation, all of which contribute to reduced downtime and extended lifespan of transmission infrastructure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Electrical Transmission Compression Fittings' category

Back to top