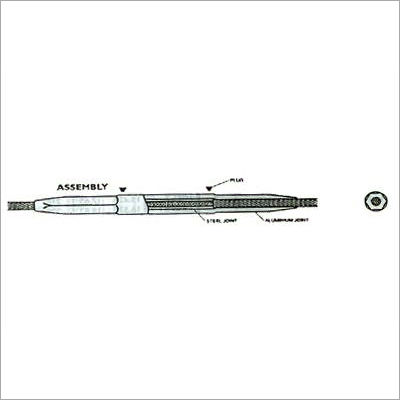

Mid Span Compression Joint

Product Details:

- Product Type Mid Span Compression Joint

- Material High Strength Aluminum Alloy and Steel

- Welding Standard Friction Welding / Compliant to IS Standards

- Capacity 16 Sq.mm to 800 Sq.mm Conductor

- Application Transmission Lines/Overhead Conductors

- Galvanization Standard IS 2629 / IS 2633 Complied

- Out Coating Hot Dip Galvanized

- Click to view more

Mid Span Compression Joint Price And Quantity

- 200.00 - 1000.00 INR/Set

- 200 INR/Set

- 10 Set

Mid Span Compression Joint Product Specifications

- High Strength Aluminum Alloy and Steel

- Friction Welding / Compliant to IS Standards

- Galvanized Coating

- Upto 400 kV Suitable

- Mid Span Compression Joint

- Hot Dip Galvanized

- Cylindrical

- 16 Sq.mm to 800 Sq.mm Conductor

- Silver Grey

- IS 2629 / IS 2633 Complied

- Precision Engineered, Smooth Finish

- Transmission Lines/Overhead Conductors

- IS/IEC 61284

Mid Span Compression Joint Trade Information

- Per Week

- Week

- as per customer requirement

- All India

- ISO 9001:2008

Product Description

Owing to our vast experience in this field, we are able to manufacture and supply best-in-class Precision Joint Connectors. These are made using the best quality materials available in the market. Our skilled team members manufacture these connectors using advanced tools and machines in our huge infrastructure facility. Also, our expert quality controllers check every connector for flaws and errors to ensure the well-being of our clients. To meet the demands of our customers, we offer these Precision Joint Connectors in many specifications.

Features:

-

Perfect design

-

Easy to fit

-

Durable

-

Fine finish

Technical Specifications

| Cat No. | Code Name | Dimensions (mm) | After comp. Flat to Flat | ||||

| Length | Outside dia | St. Length | Steel dia | Alum. | Steel | ||

| MTCJ-200 MTCJ-201 MTCJ-202 | Dog Hyena Leopard | 508 508 508 | 30 30 30 | 159 159 159 | 12.1 12.1 12.1 | 25 25 25 | 10.1 10.1 10.1 |

| MTCJ-203 MTCJ-210 MTCJ-211 | Coyote Tiger Wolf | 508 559 559 | 30 30 30 | 159 178 178 | 12.1 15.2 15.2 | 25 25 25 | 10.1 12.7 12.7 |

| MTCJ-220 MTCJ-221 MTCJ-222 | Lynx Panther Lion | 610 610 610 | 33 38 38 | 203 203 203 | 18 18 18 | 26.7 32 32 | 15.1 15.1 15.1 |

| MTCJ-230 MTCJ-231 MTCJ-232 | Bear Goat Antelope | 686 686 686 | 38 43 43 | 228 241 228 | 19.2 19.2 19.2 | 32 36 36 | 16.1 16.1 16.1 |

| MTCJ-240 MTCJ-241 MTCJ-242 | Sheep Zebra Camel | 711 711 711 | 48 48 48 | 248 241 248 | 20.8 19.2 20.8 | 40 40 40 | 17.5 16.1 17.5 |

| MTCJ-250 MTCJ-251 MTCJ-252 | Deer Elk Moose | 737 737 737 | 48 48 54 | 248 248 248 | 24 24 20.8 | 40 40 46 | 20.2 20.2 17.5 |

Engineered for Reliable Outdoor Performance

Designed with superior corrosion resistance and precision engineering, this compression joint ensures reliable connectivity for mid-span repairs in power transmission networks. Its smooth finish and hot dip galvanized coating comply with IS standards, making it ideally suited for harsh outdoor conditions across Indias diverse climates.

Versatile Application across Conductor Types

The joint accommodates multiple conductor materials, including ACSR, AAC, AAAC, and copper, ranging from 16 Sq.mm to 800 Sq.mm. Its clamp-type compression fitting and hydraulic installation method simplify field usage, providing secure mechanical strength for both routine maintenance and emergency repairs on transmission lines.

Standards Compliance and Quality Assurance

Compliant with IS 2121/Part II for mechanical strength and galvanization standards IS 2629 / IS 2633, the joint boasts high tensile durability and effective surface protection. Friction welding technology further guarantees solid joints, while packaging options include carton boxes or wooden crates, ensuring safe transportation and storage.

FAQs of Mid Span Compression Joint:

Q: How is the Mid Span Compression Joint installed on transmission conductors?

A: Installation of the joint requires a hydraulic compressor or a suitable crimping tool. The compression fitting securely clamps conductors through precision engineering, ensuring robust connection while meeting industry standards for mechanical strength.Q: What types of conductors are compatible with this compression joint?

A: This product is suitable for a range of conductors including ACSR, AAC, AAAC, and copper. It supports conductor sizes from 16 Sq.mm to 800 Sq.mm, offering versatility for various transmission line requirements.Q: When should this joint be used for conductor repairs?

A: The mid span compression joint is ideal for repairing or joining damaged mid-span sections on transmission lines. It ensures electrical continuity and mechanical stability, reducing downtime during maintenance or emergencies.Q: Where can this compression joint be applied in electrical systems?

A: The joint is primarily used in transmission lines and overhead conductor installations, suitable for outdoor environments due to its excellent corrosion resistance and hot dip galvanized surface treatment.Q: What are the benefits of using hot dip galvanized and friction-welded joints?

A: Hot dip galvanization provides superior corrosion resistance, extending joint life even under harsh weather. Friction welding or IS standard-compliant joints offer strong, reliable connections for safe performance in high voltage scenarios up to 400 kV.Q: Which packing options are available and what is the minimum order quantity?

A: Mid Span Compression Joints are available in carton boxes or wooden crates, ensuring secure transport. The minimum order quantity is 100 pieces, suitable for bulk supply to distributors, manufacturers, suppliers, or traders.Q: What standards and certifications does this joint comply with?

A: The joint conforms to IS 2121/Part II for mechanical strength, IS/IEC 61284 for engineering application, and IS 2629 / IS 2633 for galvanization. These certifications assure reliability, safety, and durability in line with Indian and international standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+