Call Us08045800593

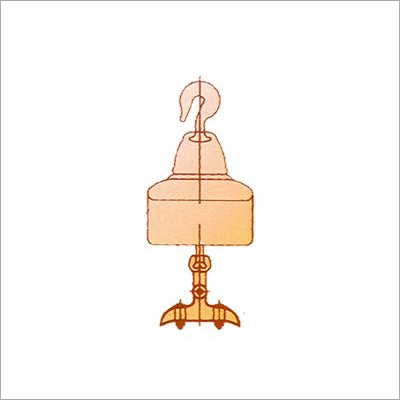

Disc Suspension Insulator

250.00 - 1000.00 INR/Set

Product Details:

- Product Type Disc Suspension Insulator

- Material Porcelain/Ceramic

- Capacity Up to 120 kN mechanical strength

- Protection High resistance to weathering, hydrophobic surface

- Output Voltage Up to 33 kV or higher per unit

- Output Type AC line insulation

- Application Transmission and distribution line insulation

- Click to view more

X

Disc Suspension Insulator Price And Quantity

- 250.00 - 1000.00 INR/Set

- 10 Set

Disc Suspension Insulator Product Specifications

- AC line insulation

- High resistance to weathering, hydrophobic surface

- Up to 33 kV or higher per unit

- Brown/Light Grey glass glaze

- Approx. 4.5 kg per unit

- Transmission and distribution line insulation

- Approx. 255 mm (Diameter) x 145 mm (Height)

- Porcelain/Ceramic

- Standard/Customized as per requirement (typically 255 mm diameter, 145 mm height)

- Up to 120 kN mechanical strength

- Disc Suspension Insulator

Disc Suspension Insulator Trade Information

- as per order Per Week

- 15-45 Days

- as per requirement

- All India

- ISO 9001:2008

Product Description

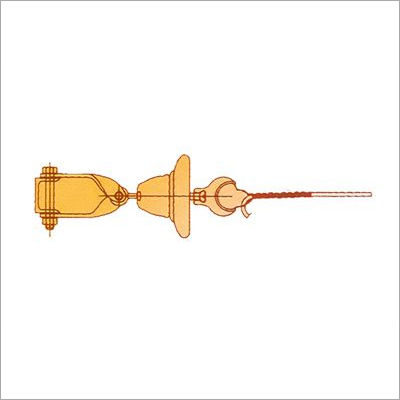

Our clients can avail from us top quality Disc Type Single Suspension Insulator. The offered insulators are manufactured in various specifications to meet the exact needs of our customers. Supreme grade materials are used by our skilled professionals to manufacture sturdy products. Owing to the non-corrosive nature and accurate dimensions, the Disc Type Single Suspension Insulator is widely appreciated by electrical industries and plants.

Features:

-

Durable

-

Easy to fit

-

Perfect design

Superior Insulation Performance

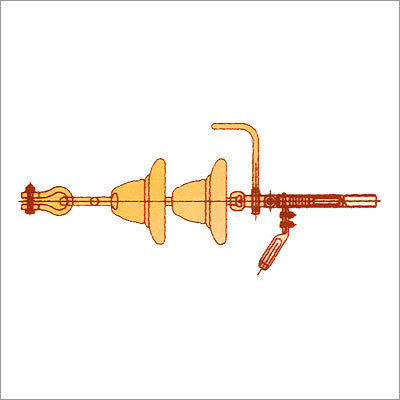

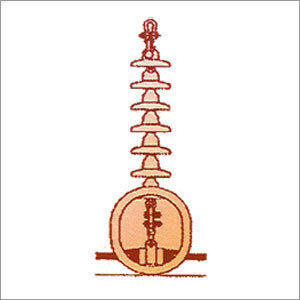

Disc suspension insulators provide robust insulation for transmission and distribution lines, with a high electrical puncture voltage exceeding 130 kV and optimized creepage distance, ensuring minimal risk of flashover in harsh outdoor environments. Their hydrophobic glazed surfaces carry excellent resistance to weathering and contamination.

Versatile Mechanical Strength

Available in multiple strength ratings up to 120 kN, these insulators suit varied mechanical load requirements. Their durable construction allows for reliable suspension in long-span overhead installations, ensuring structural safety under tensile stresses and adverse weather conditions.

Adaptable Mounting and Sizing

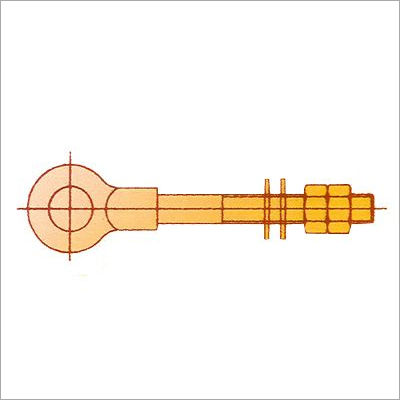

With mounting options like ball & socket or clevis & tongue, and dimensions customizable to project specifications, these insulators integrate seamlessly into diverse network configurations. Standard sizes guarantee interchangeability and ease of replacement during maintenance.

FAQs of Disc Suspension Insulator:

Q: How do disc suspension insulators protect overhead transmission lines?

A: Disc suspension insulators electrically separate conductors from grounded support structures. Their high puncture voltage and hydrophobic ceramic design minimize leakage currents and reduce the likelihood of flashovers, even in heavy pollution or wet conditions.Q: What is the installation process for these disc suspension insulators?

A: Installation is performed outdoors by suspending the insulators along transmission or distribution lines using ball & socket or clevis & tongue fittings. The units are mounted between the tower and conductor to provide mechanical support and electrical insulation.Q: When should I choose standard or customized insulator sizing?

A: Standard sizes (typically 255 mm diameter, 145 mm height) suit conventional line configurations. Customized sizing is recommended for unique projects, non-standard clearances, or specific electrical and mechanical requirements not covered by standard units.Q: Where are these insulators typically used?

A: These insulators are primarily used in overhead transmission and distribution networks, especially in environments exposed to significant pollution or varying weather conditions. Theyre vital for lines requiring up to 33 kV insulation per unit.Q: What benefit does the high creepage distance of 320 mm offer?

A: A creepage distance of 320 mm helps prevent surface tracking and flashover by providing a longer path for leakage current. This is especially advantageous in polluted or coastal zones where contamination can compromise insulation.Q: Which mounting options are available and how do I select them?

A: Mounting types include ball & socket for easier assembly and angular movement, or clevis & tongue for straightforward, secure installations. Selection depends on tower design, conductor type, and required mechanical flexibility.Q: What packaging ensures safe delivery of the insulators?

A: Insulators are packed in durable wooden crates or per export packaging standards, protecting them against shocks, moisture, and handling damage during transit, ensuring they arrive ready for installation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Electrical Hardware' category

Back to top