Call Us08045800593

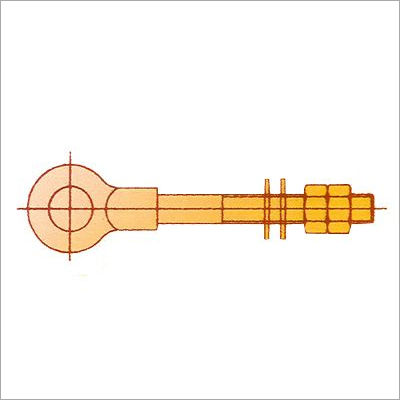

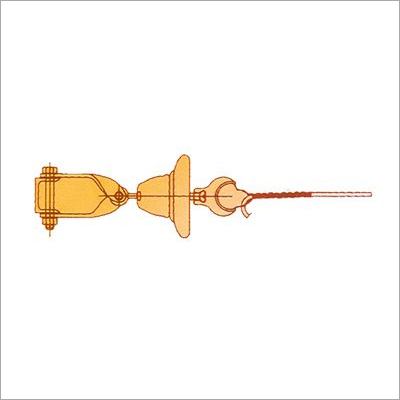

Disc Type Insulator Hardware

150.00 - 250.00 INR/Set

Product Details:

- Product Type Disc Type Insulator Hardware

- Material Galvanized Steel, Forged Steel, Malleable Iron, Stainless Steel

- Capacity Upto 120kN mechanical strength

- Protection Corrosion Resistant Coating

- Application Overhead Transmission Lines, Electrical Distribution Networks

- Size Standard sizes: 11kV, 22kV, 33kV, 66kV

- Weight 1.2 kg to 6.0 kg (depending on design)

- Click to view more

X

Disc Type Insulator Hardware Price And Quantity

- 150.00 - 250.00 INR/Set

- 25 Set

Disc Type Insulator Hardware Product Specifications

- Galvanized Steel, Forged Steel, Malleable Iron, Stainless Steel

- Disc Type Insulator Hardware

- Depends on type; typically 255mm 146mm 135mm

- Corrosion Resistant Coating

- Upto 120kN mechanical strength

- Silver, Metallic Grey

- 1.2 kg to 6.0 kg (depending on design)

- Overhead Transmission Lines, Electrical Distribution Networks

- Standard sizes: 11kV, 22kV, 33kV, 66kV

Disc Type Insulator Hardware Trade Information

- as per order Per Week

- 15-45 Days

- as per requirement

- All India

- ISO 9001:2008

Product Description

Keeping in mind the well-being of our clients, we are offering Disc Type Insulator Hardware. The offered insulator hardware is designed by our talented engineers by making use of modern tools and technology. Quality materials are used to manufacture these components to ensure longer service life and excellent design. To ensure the satisfactions of our clients, we design the Disc Type Insulator Hardware as per our patrons' demands.

Features:

-

Easy to fit

- Excellent electricity conductivity

-

High insulation capability

Superior Corrosion Resistance

Our disc type insulator hardware features a hot dip galvanized surface coating conforming to IS 2629 standards. This protective layer safeguards against oxidation, moisture, and environmental wear, ensuring long-lasting performance even in harsh weather conditions.

Versatile Fitting Options

Designed with either ball & socket or tongue & clevis fittings, these products support both suspension and tension applications. Installation is streamlined and secure, accommodating various network configurations and voltages to suit your transmission requirements.

Robust Mechanical Strength

Engineered for reliability, the insulator hardware delivers mechanical capacities up to 120kN. Built from galvanized steel, forged steel, malleable iron, or stainless steel, every component provides strength and stability under demanding loads in electrical networks.

FAQs of Disc Type Insulator Hardware:

Q: How is disc type insulator hardware installed in transmission lines?

A: Disc type insulator hardware is installed using either ball & socket or tongue & clevis fittings, suitable for both suspension and tension applications on overhead transmission lines and electrical distribution networks. Detailed installation processes vary based on site requirements and fitting type.Q: What materials are used in manufacturing disc type insulator hardware?

A: These hardware components are made from galvanized steel, forged steel, malleable iron, or stainless steel, ensuring durability and mechanical performance across standard voltage ratings from 11kV to 66kV.Q: When should the disc type insulator hardware be replaced or checked for maintenance?

A: Regular inspection is recommended to ensure hardware integrity. Replacement should be considered if there are signs of mechanical damage, corrosion beyond the galvanization protection, or performance degradation due to environmental factors.Q: Where can disc type insulator hardware be applied?

A: The hardware is ideal for overhead transmission lines and electrical distribution networks, supporting both suspension and tension systems for various mechanical and voltage requirements.Q: What is the packing process for disc type insulator hardware?

A: For safe transit and handling, hardware is packed in sturdy wooden crates or pallets. This protects the components from damage during shipping and ensures they arrive ready for installation.Q: How does hot dip galvanizing improve the products longevity?

A: Hot dip galvanizing, as per IS 2629, provides a durable coating that offers high corrosion resistance. This significantly extends the service life of the hardware, minimizing maintenance needs and enhancing operational reliability.Q: What are the main benefits of using stainless steel or brass locking pins?

A: Stainless steel or brass cotter pins are highly resistant to corrosion and wear, ensuring secure locking, reduced maintenance, and dependable performance throughout the lifespan of the hardware in diverse climatic conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Electrical Hardware' category

Back to top