Tension Assemblies EHV Lines

7000.00 - 15000.00 INR/Set

Product Details:

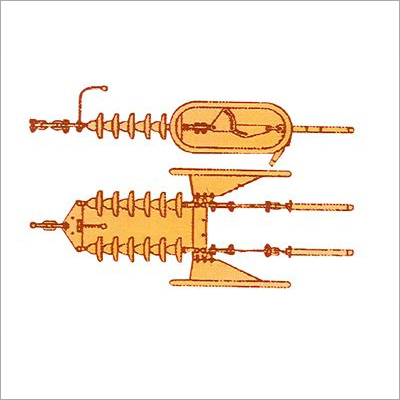

- Product Type Tension Assembly for EHV Transmission Lines

- Application Transmission & Distribution of Electrical Power, EHV/ UHV line installations

- Size Customized to line requirements (various sizes available)

- Weight Depends on size and type (approx. 25kg to 220kg per assembly)

- Dimension (L*W*H) Standard and custom configurations available, varies as per contract drawing

- Color Metallic silver / galvanized finish

- Click to view more

X

Tension Assemblies EHV Lines Price And Quantity

- 15 Set

- 7000.00 - 15000.00 INR/Set

Tension Assemblies EHV Lines Product Specifications

- Tension Assembly for EHV Transmission Lines

- Customized to line requirements (various sizes available)

- Metallic silver / galvanized finish

- Transmission & Distribution of Electrical Power, EHV/ UHV line installations

- Standard and custom configurations available, varies as per contract drawing

- Depends on size and type (approx. 25kg to 220kg per assembly)

Tension Assemblies EHV Lines Trade Information

- as per order Per Week

- 15-45 Days

- as per requirement

- All India

- ISO 9001:2008

Product Description

We are a reputed organization, engaged in manufacturing and supplying superior grade Tension Assemblies EHV Lines. These lines are widely demanded by our customers for their perfect dimension and durability. We manufacture these lines using the best quality steel and other materials to ensure maintenance free service. Our clients can avail these lines in many specifications and sizes to meet the demands of our customers. Furthermore, we offer these Tension Assemblies EHV Lines in safe packaging to ensure security from any any kind of damage during transit.

Features:

-

Corrosion resistant

-

Longer service life

-

Flawless finish

Superior Mechanical Performance

Engineered for high-strength applications, these tension assemblies undergo rigorous type testing as per IS/IEC standards. Capable of handling mechanical loads up to 120 kN, they provide excellent shock and vibration resistance, ensuring stability and safety for EHV and UHV line installations.

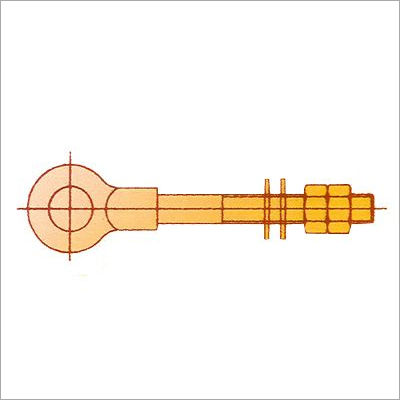

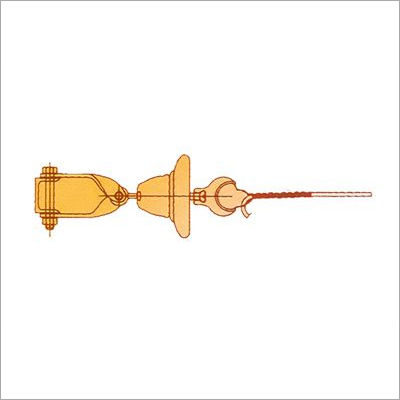

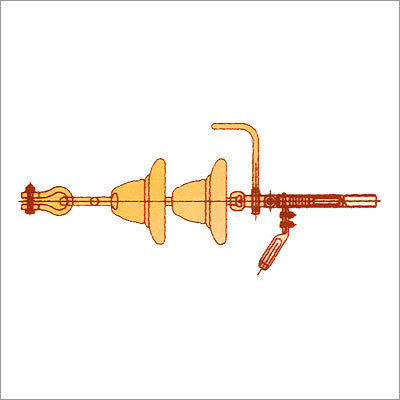

Versatile Design and Customization

Choose from various fitting types, including ball & socket, clevis, and eye/fork, to suit different line designs and installation needs. Assemblies are configurable for both single and twin conductor bundle configurations, and can be customized to specific mechanical and dimensional requirements.

Long Service Life with Minimal Maintenance

Built for durability, tension assemblies feature high-quality galvanized finishes for corrosion resistance and are designed to function efficiently for over 30 years under normal conditions. Periodic inspection is recommended, but regular maintenance needs are minimal.

FAQs of Tension Assemblies EHV Lines:

Q: How are tension assemblies for EHV lines installed on single and twin conductor bundles?

A: Tension assemblies are designed for flexible installation and can be easily adapted for both single and twin conductor bundle configurations. The fitting typeball & socket, clevis, or eye/forkis selected as per line design, enabling secure attachment and structural integrity.Q: What standards do these tension assemblies comply with?

A: Assemblies are manufactured in accordance with leading industry standards such as IS, IEC, and ASTM. Additionally, they may be customized or tested to meet specific customer or project requirements to ensure full compliance.Q: When should periodic inspections or maintenance be conducted?

A: Although the assemblies require minimal maintenance, periodic inspections are recommended to ensure continued mechanical reliability and identify any potential wear or environmental impact, preserving their expected life span of over 30 years.Q: Where are these assemblies typically used?

A: They are primarily used in transmission and distribution of electrical power, especially within EHV/UHV line installations. Their robust construction makes them suitable for harsh environments and demanding power line applications.Q: What is included in the structure of a typical tension assembly?

A: A standard assembly includes components such as yoke plates, tension clamps, suspension hardware, arcing horns, bolts, and nuts. These elements work together to support conductors and safeguard the line infrastructure.Q: How does the customization process work for tension assemblies?

A: Customers can specify requirements such as tensile strength, fitting type, size, and configuration based on their line design. The manufacturer collaborates on design drawings and produces assemblies tailored to unique project specifications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Electrical Hardware' category

Back to top