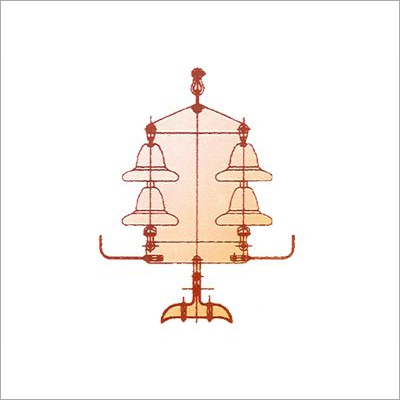

Double Suspension Hardware Disc Insulator fittings

Product Details:

- Product Type Suspension Hardware Fittings for Disc Insulator

- Material Galvanized Steel, Ductile Iron, Alloy Steel

- Capacity Suitable for Double Suspension String Configuration

- Protection Corrosion Resistant, Weatherproof

- Application Overhead Transmission Lines, High Voltage Insulation

- Size Standard sizes available for various voltage levels; customizable

- Weight Varies by assembly, typically 815 kg

- Click to view more

X

Double Suspension Hardware Disc Insulator fittings Price And Quantity

Double Suspension Hardware Disc Insulator fittings Product Specifications

- Corrosion Resistant, Weatherproof

- Galvanized Steel, Ductile Iron, Alloy Steel

- Overhead Transmission Lines, High Voltage Insulation

- Varies by assembly, typically 815 kg

- Suitable for Double Suspension String Configuration

- Metallic Silver (Zinc Coated)

- Standard sizes available for various voltage levels; customizable

- As per design, commonly 400mm x 350mm x 80mm

- Suspension Hardware Fittings for Disc Insulator

Double Suspension Hardware Disc Insulator fittings Trade Information

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- All India

Product Description

In order to fulfill the demands of our clients, we are offering our valued clients with Double Suspension Hardware Disc Insulator. Used for insulating heat and electricity, these insulators are widely used in electrical towers and power plants. Our vendors supply us with top quality materials, which are used to manufacture these insulators. The Double Suspension Hardware Disc Insulator is made with the help of identical shaping mold in our huge infrastructure facility.

Features:

-

Dimensionally accurate

-

Durable

-

Smooth finish

Exceptional Mechanical Strength

Engineered for demanding applications, these fittings provide tensile strength between 90kN and 160kN. Their construction from high-grade alloys ensures reliability under sustained load and environmental stress, making them ideal for high-voltage transmission infrastructures.

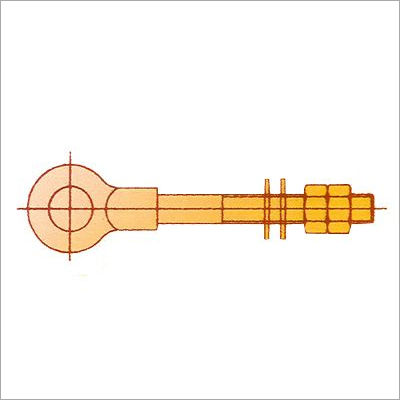

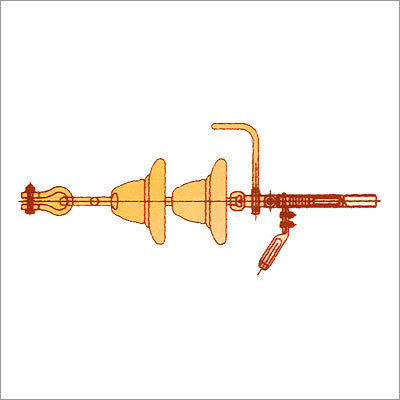

Versatile Mounting and Installation

Double Suspension Hardware Disc Insulator Fittings support bolted or pin-type mounting, with suspension clamp, ball & socket, or clevis arrangements for optimal flexibility. Installation is efficient and secure, adaptable to the needs of diverse transmission line projects.

Corrosion Resistance and Weatherproof Protection

Finished with a hot dip galvanized coating, the metallic silver appearance offers lasting corrosion resistance and weatherproof performance. These attributes protect the insulator fitting in harsh outdoor conditions, ensuring longevity and minimal maintenance.

FAQs of Double Suspension Hardware Disc Insulator fittings:

Q: How are the Double Suspension Hardware Disc Insulator fittings installed on transmission lines?

A: Installation typically involves securing the fittings with suspension clamps and either ball & socket or clevis connections, complemented by bolted or pin-type mounting. The process is straightforward and accommodates both standard and custom string configurations.Q: What mechanical strength do these fittings provide for overhead transmission applications?

A: They offer impressive tensile strength, ranging from 90kN up to 160kN, ensuring durability and resistance to mechanical stresses commonly encountered in high-voltage environments.Q: When should these insulator fittings be used in transmission line projects?

A: They are recommended for overhead line systems requiring high tensile strength and reliable insulationparticularly where double suspension string configurations are needed for voltages between 11kV and 765kV.Q: Where are these fittings commonly utilized across the power grid?

A: Double Suspension Hardware Disc Insulator fittings are widely used throughout India in projects involving overhead high-voltage transmission lines, including utilities, substations, and grid expansion initiatives.Q: What is the benefit of hot dip galvanizing on these insulator fittings?

A: Hot dip galvanized finishes provide robust corrosion and weather resistance, greatly extending the service life of the fittings, even under severe outdoor conditions.Q: Which accessories are included with these insulator hardware assemblies?

A: The assemblies come complete with essential components such as yoke plates, clevis, ball & socket fittings, pins, and bolts, ensuring hassle-free installation and reliable operational performance.Q: Can the size and configuration of these fittings be customized for specific voltage levels?

A: Yes, while standard sizes are available, customization is offered to match the dimensional and operational requirements of different voltage levels and transmission projects.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Electrical Hardware' category

Back to top